Welcome to the second edition of our Basics of Injection Molding blog series. In this edition we will look at what the next steps are in moving forward with an injection molded plastics project. What do you do, where do you go, what questions should you ask? Those are all questions we have had proposed to us when a prospective customer or current customer comes to us with a new project, especially a custom injection molded plastics product.

FIRST STEPS

GETTING STARTED ON AN INJECTION MOLDED PLASTICS PROJECT

So, let’s dive in, you settled on injection molding as your manufacturing method, what next? You need to find an injection molder to take your project to, and help you get the process started. What is the first thing you can do to benefit you the customer needing to purchase an injection molded plastic part. The first thing you can do if you need an injection molded plastic part is to familiarize yourself with what injection molding is and how it works.

- The Injection Molding Process

- Injection Molding Terminology

- The Tool or The Mold

- What Injection Molders Need to Quote

You may not understand much of the information, but having a frame of reference for these items is critical to selecting the injection molding company that is best for your needs. We suggest to do some initial research on injection molding. Perhaps find a blog with information about injection molding, or research videos about the topic on YouTube. You could visit our HTI Plastics YouTube channel with several videos about injection molding and the injection molding process.

RESEARCH

Researching the terminology associated with injection molding can be very helpful, and also save time on the initial conversations. Having that foundation of what the injection molding company is talking about can make a big difference at the start of a project. Furthermore, it can be very helpful to do some research on what an injection molding tool or an injection molding mold is and what they consist of. Understanding these items will give a company needing an injection molded plastic product the framework to have in-depth conversations early on, and get to what you are wanting and needing from the injection molder.

Perhaps the best thing you can do to start is to reach out to an injection molding company. Start by having a conversation. You can reach HTI representatives at 402-470-2600 and someone would be happy to have a conversation about your projects and the needs you have for the part. At HTI someone in our sales and service department would be happy to have an initial conversation with you and if beneficial bring in one of our on-site engineering experts to speak to the details needed on the project.

Understanding the functionality of the part, how it will be used, elements it could potentially be exposed to are key in the initial process of kicking off an injection molded plastics project. Many times, when a company is needing an injection molded plastic part, that company isn’t aware of the sheer number of types and grades of plastic resin. By understanding how, where, and how often a product will be used HTI Plastics engineering and molding experts can help suggest a material that will be the best option for your needs.

NEXT STEPS

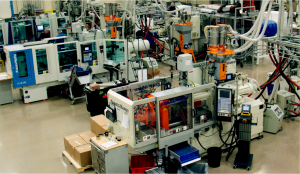

After your initial conversation with HTI Plastics about your custom injection molded project, the conversation will be driven by our engineering department. Our engineering department are highly skilled, with an intense training background in scientific molding and the design for manufacturability. Our engineering department can take your initial concept or design and optimize it for the manufacturing process. If you are able set up a face-to-face meeting with the team working on your project. At HTI we welcome our customers to come in to visit our facility and talk directly with our team. HTI Plastics does work with customers all over the globe, so it time and distance is an issue, we would suggest setting up a virtual meeting. In this next phase our engineering team will discuss details of the project with you regarding the design and go over all of the information and details needed to quote the project. We will get into more detail on what is needed to quote the project in the next edition of the Basics of Injection Molding blog series.

DESIGN

If you don’t have a design in place or are not able to create official prints or a CAD file, HTI can help you take your idea and make it a reality, even if it is a doodle on a napkin! Once the design is complete, finalized and approved, HTI would work with our robust network of tooling partners on gather quotes and then ultimately build the tool.

MOVING FORWARD

To wrap it up, the best thing a company needing a custom injection molded plastic product made can do to get started is to do some initial research and then reach out directly to injection molding companies. At HTI Plastics, we understand it can be overwhelming to take on this project feel like you don’t know where to start or who to turn to for guidance. HTI Plastics is here for you. We enjoy having these initial conversations and seeing a project grow from an idea being discussed on a call to getting that approval on the first article parts and moving in to production runs.

HTI Plastics wants to be a true partner to our customers, and that starts from the very beginning. We hope that the second edition of the Basics of Injection Molding Blog Series was informative and has allowed you to know the steps to take and what to do when your next injection molding project arises. Our hope with this series is to provide our customers and prospective customers with the information they need to be able to make the best decision for their companies and to ensure they have all the information needed to get high quality parts with great service.

Please keep an eye out for the third edition of the blog series “Information Required to Quote your Plastic Product.”

home pic mfg